Main features:

· The machine is made of all steel plate welded, with high strength and good stability;

· After the machine is welded and tempered at high temperature, it is processed by CNC machining center, and the bottom layer is fine sandblasted to remove rust, with high corrosion resistance;

· The stroke adjustment is controlled by encoder with high-precision and convenient adjustment;

· Conventional feeding and vacuum high-pressure feeding can be used. The material level of the barrel is induced and the material can be supplied by itself

· imported angle seat valve and high-frequency valve are adopted to ensure the steam stability and save the steam consumption;

· adopting high-efficiency vacuum cooling and an independent drainage system to greatly shorten the vacuum time and reduce the water content of the product;

· Adopting PLC control and computer touch screen operation for simple and stable operation;

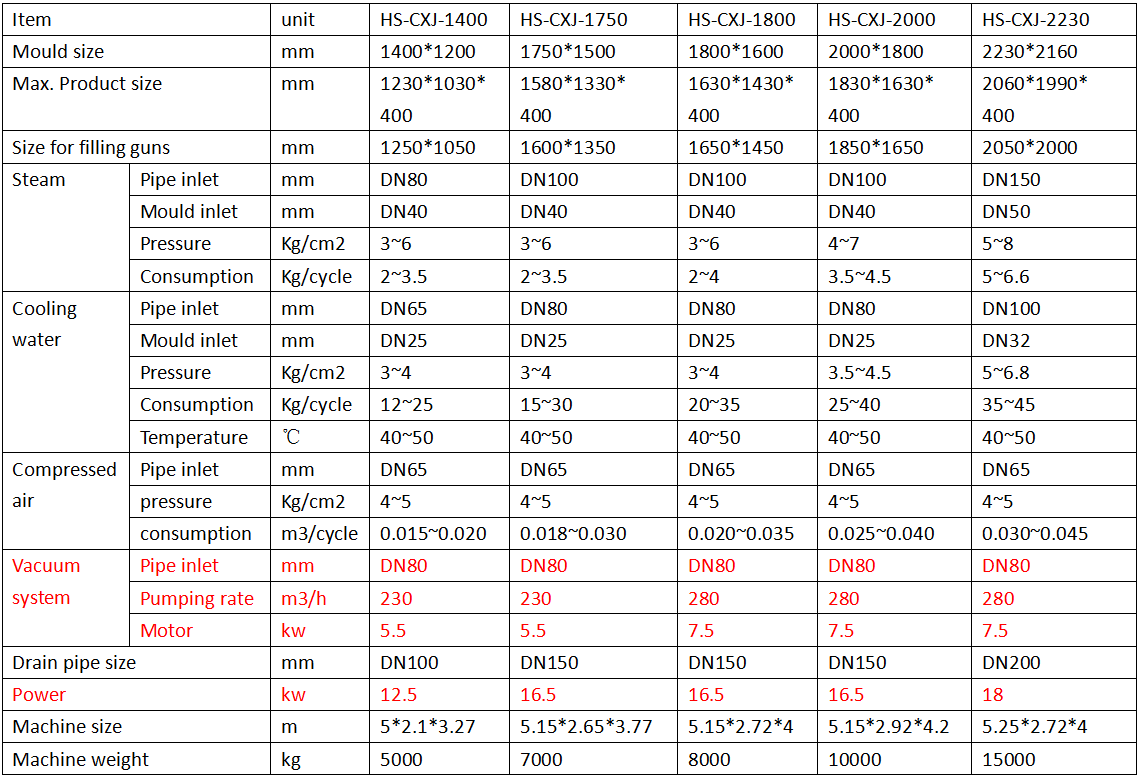

Technical data: